Solar cells: Definition, history, types & how they work

Solar cells hold the key for turning sunshine into into electricity we can use to power our homes each and every day. They make it possible to tap into the sun’s vast, renewable energy. Solar technology has advanced rapidly over the years, and now, solar cells are at the forefront of creating clean, sustainable energy from sunlight.

DID YOU KNOW… The amount of sunshine that hits the earth’s surface in just 90 minutes is enough to power the world for a whole year!

Solar panels are made up of three main parts: cells, modules, and arrays.

The solar cell is where the magic happens. This tiny unit is what captures sunlight and turns it into energy. How well a solar panel works depends on the quality and number of its cells, plus the type of solar PV system that connects everything. Over the years, solar cells have become more efficient, affordable, and widely available.

In fact, uses range from small gadgets to huge power plants.

If you’re thinking about solar energy, it’s helpful to know both the advantages and disadvantages of solar energy, so you can make the best choice.

On this page, you’ll learn:

- How solar cells work and their basic structure

- The different types of solar cells and what makes each unique

- Important factors that impact solar cell efficiency and why it matters for generating real-world energy

We have quite a bit of ground to cover on this page today. So without further ado, let’s get started!

What are solar cells?

A solar cell is a small but powerful device that converts light directly into electricity through a process called the photovoltaic effect. When sunlight—or even artificial light—hits a solar cell, it energises electrons in the cell’s semiconductor material (usually silicon). This creates a flow of electric current. This current can then power devices or, when connected with other cells, supply energy to homes, businesses, or even entire power grids.

Solar cells are the essential building blocks of solar panels. A single cell produces a small amount of electricity. However, when many cells are linked together in a solar PV system, they can produce enough power to significantly reduce or even replace traditional energy sources.

Brief history of solar cell development

Solar cells bring us a fascinating process where light is turned into electric current. This phenomenon was first observed by French physicist Edmond Becquerel way back in 1839. This discovery was the first step in understanding how sunlight could be converted into energy.

Over a century later, solar cells became the building blocks of solar panels, making it possible to harness the power of the sun in a practical way.

The big breakthrough came in 1954 when scientists Daryl Chapin, Calvin Fuller, and Gerald Pearson at Bell Labs developed the first practical silicon solar cell. This groundbreaking cell could convert about 6% of sunlight into electricity, a small fraction, but a huge step toward modern solar power.

Despite this modest start, it was a revolutionary breakthrough, proving for the first time that it was possible to generate a steady electrical current from sunlight alone. This discovery laid the foundation for today’s solar technologies, sparking decades of innovation and making solar power an increasingly viable energy source around the world.

By the late 1950s and early 1960s, silicon solar cells saw rapid efficiency improvements. These improvements were reaching about 10% efficiency, talk about a significant leap forward! These improvements came just in time for the space race. This is where solar cells proved ideal for providing long-lasting power to satellites and other space vehicles.

In 1958, the Vanguard I satellite was launched. It became the first spacecraft to use solar cells as a power source. This marked an important milestone for solar technology. Since then, solar cells have continually advanced in both efficiency and affordability, becoming one of the key solutions for renewable energy on Earth.

How solar cells work

Solar cells work by converting sunshine directly into electrical energy through the process we keep raving about called the photovoltaic effect. So, when sunlight, or solar radiation hits a solar cell, the energy from the light excites electrons within the cell’s semiconductor material, which is usually silicon. This energy boost allows the electrons to move more freely, thus creating an electric current.

When we talk about this in technical terms, a p-n junction is a boundary between positively and negatively charged layers in the cell. It produces a built-in electric field. This field directs the excited electrons in a specific direction. It creates a flow of direct current, which we commonly refer to as DC electricity and can be used for power.

Because most household and commercial appliances require alternating current, which we commonly refer to as AC electricity, the DC electricity produced by solar cells is routed through an inverter. This device works its magic by converting DC into AC. It makes the power produced by solar panels compatible with common electrical systems.

By capturing and transforming sunlight in this way, solar cells provide a clean, renewable source of electrical power. It can then be used immediately, stored in solar batteries, or even sent back to the electric grid.

This entire process, from sunlight striking the cell to generating usable electricity, is efficient and has no moving parts. This is one of the reasons why solar cells are highly durable. The photovoltaic effect is foundational to all solar technology and continues to improve as new materials and methods increase solar cell efficiency and power output.

Solar cell structure and operation

The basic structure of a solar cell is carefully designed. This way, it can maximise absorption and efficiently convert it into electrical energy. A typical solar cell is made of three main layers. They are the antireflection layer, energy-conversion layers, and electrical contact layers.

The antireflection layer is on the top surface and works to prevent light from bouncing away by reducing reflection. This allows more sunlight to pass through to the cell’s energy-conversion layers. It increases the amount of energy that can be absorbed and used.

Beneath the antireflection layer are the energy-conversion layers. These include:

- the top junction layer,

- absorber layer, and

- back junction layer.

These layers work together to convert sunshine into an electric current.

When light reaches the absorber layer, electrons are excited and freed. They move across the p-n junction formed by the top and back layers. This movement of electrons through the cell is the DC electricity.

Finally, electrical contact layers on both the top and bottom of the solar cell allow the generated current to flow out of the cell and into an external circuit or solar PV system. The top contact layer is usually made in a thin grid pattern to avoid blocking light, while the back layer is fully metal to capture as much current as possible.

Together, these layers create a stable, efficient system for capturing the sun’s energy and converting it into usable power.

Types of solar cells (by PV material)

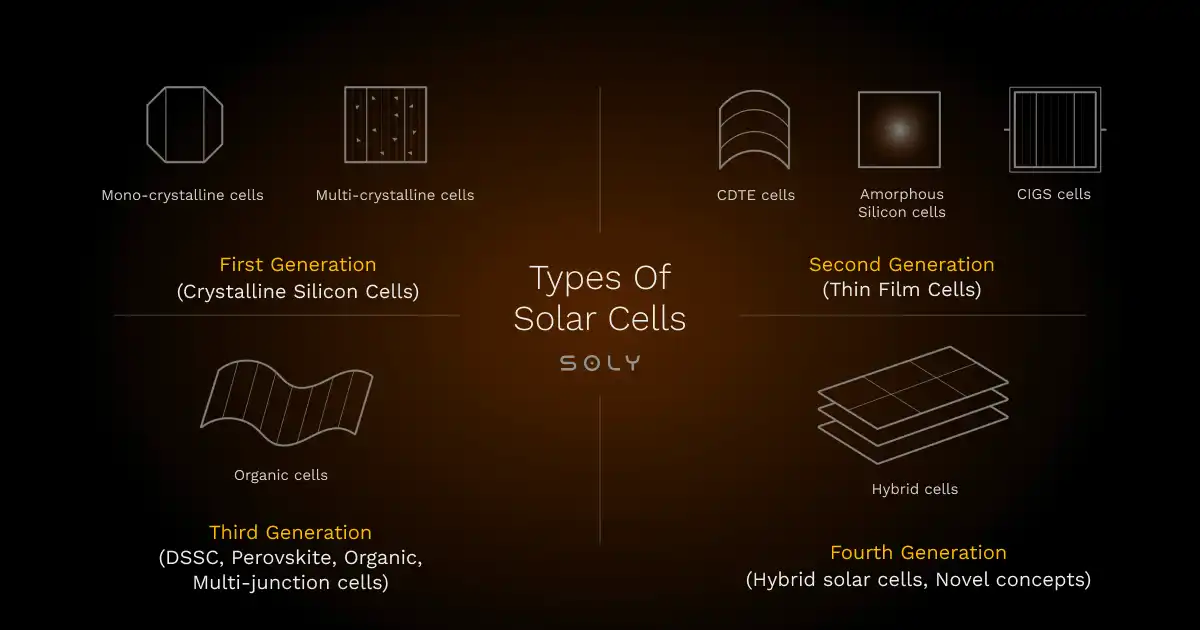

Solar cells come in various types. They each utilise different photovoltaic (PV) materials to capture sunlight and convert it into electrical energy. The most common types include crystalline silicon and thin-film.

However, there are newer technologies out there such as perovskite and organic solar cells. Each type has something unique to bring to the table when it comes to diversity and adaptability of solar PV systems in the renewable energy market today.

Crystalline silicon solar cells (c-Si)

Crystalline silicon solar cells dominate the market. In fact, they make up approximately 95% of all solar cells. They are known for their high efficiency and long lifespan. This is why they are popular for residential, commercial, and industrial use. Crystalline silicon can be processed into two main forms: monocrystalline and polycrystalline.

Crystalline silicon cells efficiently convert sunlight into electrical energy due to their structured silicon lattice. This is because it allows for an effective electron flow, which therefore maximises power output.

Monocrystalline silicon (mono-Si)

Prized for its efficiency in both electronics and solar cells is monocrystalline silicon (mono-Si):

- Material: Monocrystalline silicon is a highly pure, single-crystal form of silicon. This single-crystal structure allows electrons to flow freely. This makes it highly effective at producing power.

- Applications: Mono-Si is widely used in solar panels and can also be found in high-performance electronics, like computers and smartphones.

- Properties: Its continuous crystal structure has no grain boundaries, allowing electrons to flow smoothly.

- Efficiency: Thanks to its single-crystal structure, mono-Si is excellent at absorbing light, making it ideal for high-performance solar cells where maximum energy output is essential.

- Preparation: Monocrystalline silicon is made in its pure form or can be mixed with elements like boron or phosphorus to create p-type or n-type silicon, which enhances its ability to convert energy.

- Significance: Known as the backbone of the “silicon era,” mono-Si’s availability and efficiency have played a huge role in driving advancements in both solar and electronics technology.

- Comparison: Unlike polycrystalline silicon (made of multiple crystals) and amorphous silicon (which has no crystal structure), mono-Si stands out for its superior efficiency and durability—though it does cost more to produce.

Keep on reading: Monocrystalline Solar Panels Explained – From A to Z

Polycrystalline silicon (multi-Si)

A cost-effective alternative to mono-Si, polycrystalline silicon. It’s used in both the solar photovoltaic industry and electronics:

- Material: Polycrystalline silicon is a high-purity silicon made up of many tiny crystals, called crystallites, giving it a unique “metal-flake” look.

- Production: Poly-Si is made by purifying raw silicon using methods like the Siemens process or fluidised bed reactors. The purified silicon is then formed into multicrystalline ingots or single-crystal boules, which are sliced into wafers for solar cell production.

- Purity: For electronics, polysilicon is refined to extremely low impurity levels—below one part per billion. Solar-grade polysilicon (SoG-Si) doesn’t need to be as pure, which helps keep costs down.

- Global production: Most polycrystalline silicon is now produced in China, which controls around 90% of the global manufacturing capacity.

- Applications: Poly-Si is widely used in solar cells, especially as the PV market grows. Approximately 5 tonnes of material is needed for each megawatt of standard solar modules.

- Comparison: Polycrystalline cells aren’t as efficient as monocrystalline cells because grain boundaries can slow electron flow, but they are more affordable and simpler to produce.

Keep on reading: Polycrystalline Solar Panels Explained – Key insights

Thin-film solar cells

Thin-film solar cells offer a flexible and lightweight alternative to traditional silicon-based cells. They’re ideal when a solar project necessitates adaptability:

- Composition: Thin-film solar cells are made by layering ultra-thin photovoltaic materials onto surfaces like glass, plastic, or metal. These layers are incredibly slim, ranging from just a few nanometers to microns, making them much thinner than traditional solar cells.

- Materials Used: Most thin-film cells are made from materials like cadmium telluride (CdTe), copper indium gallium selenide (CIGS), and amorphous silicon (a-Si). Newer options include perovskite, organic compounds, and quantum dots, known as third-generation materials.

- Generations: Thin-film technology is known as second-generation, following first-generation crystalline silicon cells. Third-generation materials aim to push efficiency and cost-effectiveness even further over time.

- Advantages: Thin-film cells are lightweight and flexible, making them perfect for building-integrated projects and photovoltaic windows. Their flexibility allows them to fit on curved surfaces or structures where traditional, rigid panels may not work.

- Efficiency: Some thin-film cells, like single-junction designs, reach up to 29.1% efficiency, while advanced multi-junction cells can achieve as high as 47.6% efficiency, outperforming some traditional silicon cells.

- Environmental Impact: Thin-film cells typically have a lower carbon footprint during production and reduced toxicity, making them a cleaner option compared to many other energy sources.

- Market Share and Lifespan: Thin-film cells make up about 5% of the global solar market. While they generally have a shorter lifespan and higher degradation rates, they remain popular in the U.S., where CdTe cells alone account for roughly 30% of new utility-scale installations.

Keep on reading: Thin-Film Solar Panels Explained – Complete Overview

Other materials used in thin-film and other solar-cell technologies:

Researchers have developed a variety of materials that go beyond traditional silicon with aims to improve flexibility, efficiency, and cost effectiveness.

What’s more, these materials allow solar cells to adapt to new environments. Each material has specific properties that make it suitable for different applications. Here’s a look at some of the materials used in thin-film and emerging solar cell technologies:

- Amorphous silicon (a-Si):Amorphous silicon is a flexible, lightweight, non-crystalline form of silicon, making it ideal for thin-film solar cells. While it’s less efficient than crystalline silicon, its flexibility allows it to be applied to curved surfaces and even windows, opening up more options for solar power integration.

- Nanocrystalline silicon (nc-Si): Nanocrystalline silicon blends the qualities of crystalline and amorphous silicon, with tiny crystal structures embedded in a non-crystalline matrix. This unique setup helps it absorb light better, making it especially useful for indoor or low-light conditions.

- Proto Crystalline silicon (pc-Si): Protocrystalline silicon sits somewhere between amorphous and nanocrystalline silicon in structure. Its stability makes it a great choice for solar cells that need to handle changing light conditions, and it’s often used to enhance the stability of thin-film solar cells.

- Cadmium Telluride (CdTe): CdTe is a widely used non-silicon material in thin-film solar cells because it’s both cost-effective and efficient at converting sunlight into electricity. It’s especially popular in large-scale solar installations. However, because it contains cadmium, it requires careful handling.

- Copper Indium Gallium Selenide, (CIGS): CIGS is known for being one of the most efficient thin-film solar cell materials. It’s flexible and can be applied to different surfaces, making it versatile for various installations. While it performs well, it’s also more complex and costly to produce compared to CdTe.

- Emerging photovoltaics: This category includes exciting new materials like perovskites, organic compounds, and quantum dots. Although these are still being developed, they show a lot of promise for the future of solar technology (more on these below).

- Multi-junction solar cells (MJ): MJ cells are made with multiple layers, each capturing different parts of the light spectrum, making them extremely efficient—some even reach over 46% efficiency with concentrated sunlight. Because they’re complex and costly to produce, MJ cells are mainly used in specialised applications, like powering spacecraft and in concentrator photovoltaics (CPV) systems in areas with intense sunlight.

Emerging photovoltaics and novel solar cells

Here’s a closer look at the emerging photovoltaics and novel solar cells that hold potential due to their unique advantages:

Perovskite solar cells

Perovskite solar cells are an exciting development in solar technology. They use a perovskite-structured material as the active layer for light absorption. These cells are promising because they can be manufactured more affordably and potentially achieve higher efficiencies than traditional silicon solar cells.

Perovskites are also lightweight and can be applied to flexible surfaces. This makes them versatile for many different applications. Although they’re still in the research phase, their rapid efficiency improvements make them a strong candidate for future solar technologies.

Dye-sensitised cells and their applications

Dye-sensitised solar cells (DSSCs) work through a unique photoelectrochemical process. This is where a dye absorbs sunlight and generates electrical energy.

Unlike traditional solar cells, the dye in DSSCs is responsible for light absorption, while the charge transport is handled by a separate layer. This design allows for flexibility and lower manufacturing costs. In fact, this makes DSSCs a potential alternative for applications needing transparency or flexibility, such as windows or wearable devices.

Organic solar cells

Organic solar cells are made from organic semiconductors and are processed from liquid solutions. This makes them easier and cheaper to produce in high volumes.

While their efficiency is currently lower than that of silicon-based solar cells, organic cells are incredibly flexible, lightweight, and can be applied to different surfaces. This adaptability makes them promising for portable and wearable solar applications, even though they are still in the early stages of development.

Quantum dot solar cells

Quantum dot solar cells (QDSCs) use quantum dots. These are tiny semiconductor particles that can be tuned to absorb different wavelengths by adjusting their size. This tunable bandgap allows QDSCs to capture a broader range of the solar spectrum. This makes them ideal for multi-junction cells and quite promising for reaching higher efficiencies.

As of 2022, QDSCs achieved efficiencies over 18%. Moreover, they have potential efficiencies of up to 66%. This is thanks to their ability to harness hot carriers and produce higher photovoltages and photocurrents.

All of these innovative materials continue to contribute to solar energy’s expanding potential. They support efficiency, flexibility, and diverse applications across many environments.

Type of semiconductor material: P-type vs N-type solar cells

Solar cells are made from semiconductor materials, such as silicon, that can conduct electricity better than an insulator but not as well as a good conductor like a metal.

In solar panels, the type of semiconductor material impacts both efficiency and lifespan. The two main types of semiconductors used are P-type and N-type silicon, each with unique characteristics due to the presence of positive or negative charges.

P-type solar cells

P-type solar cells are created by doping silicon with materials that have fewer valence electrons, often resulting in “holes” or positive charges. This process, which introduces elements like boron, is relatively simple and cost-effective, making P-type cells more common. They provide good performance and efficiency, though N-type cells often have certain advantages.

Pros:

- ✅ Cost-effective: P-type cells use boron-doped silicon. This makes them simpler and cheaper to produce compared to N-type solar cells.

- ✅ Much more affordable upfront: Because of lower production costs, P-type solar panels are more budget-friendly. This makes them a popular choice for residential installations.

- ✅ Widespread use: P-type technology has been around for a long time. This means it’s well-established and easier to find affordable options and reliable performance data.

Cons:

- ❌ Lower efficiency in prolonged sunlight exposure: Over time, P-type cells can experience slight degradation in efficiency because of sunlight exposure.

- ❌ Not as efficient in low-light: P-type cells tend to perform slightly less effectively in low-light conditions compared to N-type cells.

- ❌ Susceptible to light-induced degradation (LID): This can result in a gradual decrease in power output. This is especially true during the initial period of exposure.

N-type solar cells

When you add phosphorus to silicon, you get N-type solar cells. This is where an extra electron is introduced to the silicon atoms to create a “negative” charge within the material. This structure allows N-type cells to operate with high efficiency and stability even under intense sunlight and over long periods.

Unlike P-type cells, N-type cells are less susceptible to light-induced degradation (LID). That means they maintain their performance better over time. This makes them ideal for advanced solar power systems where high, consistent efficiency is absolutely necessary.

Pros:

- ✅ Greater efficiency: N-type cells can produce more electricity. This is especially the case in low-light conditions and is because of their sensitivity to long-wavelength light.

- ✅ Durable: N-type cells often have lower degradation rates and a longer lifespan. This makes them reliable for extended use.

- ✅ Better at handling temperatures: They perform well in high temperatures. This makes them perfect for locations that are accustomed to intense sunlight.

- ✅ Sleek looks: They typically have a more uniform look with less visible grid lines. This can be very appealing to consumers who are aesthetically-conscious.

Cons:

- ❌ Tend to cost more: The manufacturing process is more complex, making N-type cells more expensive than P-type.

- ❌ Limited availability: N-type technology is newer and still undergoing research. This makes it far less available and not as understood as the P-type cells.

FAQ

What is the difference between solar panels and solar cells?

Think of solar cells as the building blocks. They’re small units that convert sunlight into electricity. When multiple solar cells are put together, they form a solar panel. Working together, these cells generate more power, enough to run a home or business.

How are solar cells made?

Most solar cells are made from silicon. The silicon is processed into thin wafers and treated with special chemicals to create positive and negative layers. These layers form something called a p-n junction, which is key to generating electricity when sunlight hits the cell.

What are the three types of solar cells?

The main types of solar cells are crystalline silicon (which includes monocrystalline and polycrystalline, thin-film (using materials like CdTe and CIGS), and emerging technologies like perovskite and organic cells. Each type has its own strengths and is used in different ways depending on the application.

What are the advantages and disadvantages of solar cells?

Solar cells are great because they provide clean, renewable energy and have low running costs. However, they can be expensive upfront, and their efficiency can drop in cloudy or low-light conditions. Different materials and types offer various trade-offs between cost and efficiency.

Final thoughts: Summary of key points and takeaways

Solar cells are revolutionary devices that work to convert light into electrical energy through the photovoltaic effect. As we’ve covered comprehensively here, they’re made primarily from silicon, solar cells are the core of solar panels.

No doubt about it, they capture sunshine and turn it into usable power. Of course, solar energy offers a clean, renewable solution that reduces reliance on fossil fuels and helps lower greenhouse gas emissions.

However, with the recent advancements in photovoltaic technology, we can see that solar cells are much more efficient, affordable, and accessible. This makes solar power a viable option for everything, whether it’s a home, business, or even a large-scale application.

Indeed, as technology continues to evolve, we are seeing that solar cells will play an even bigger role in providing sustainable, cost-effective energy solutions, bringing the power of the sun to more people around the world.

Why choose Soly for your solar panel needs?

At Soly, we make solar energy accessible and ensure your photovoltaic system lasts as long as possible, performing at its best. Here’s why we’re the ideal choice for your solar energy journey:

- Affordable financing: We understand that upfront costs can be a barrier to going solar. That’s why Soly partners with Hometree Finance, helping you make the switch to clean, renewable power in an affordable way.

- Referral benefits: Soly offers the best referral scheme in the solar market. As a Soly customer, you can earn £300 for each friend you refer who installs a system with Soly—with no limits! This can significantly help reduce your payback period. For example, one of our customers, Martyn, managed to reduce his payback period by nearly a year by referring just three friends.

- High-quality panels: We use only the best solar panels, offering monocrystalline solar panels from Jinko Solar. Known for their efficiency and durability, these monocrystalline solar panels can last for up to 40 years, ensuring you get the most out of your investment.

- Trusted reputation: Soly is proud to be highly rated on platforms like TrustPilot and Google and recognized as a certified Which? Trusted Trader. We’ve built a reputation for excellence, earning the trust of countless satisfied customers, with our commitment to quality evident in every installation.

- Accredited installers: We work exclusively with local installers nationwide who are accredited by HIES, TrustMark, and MCS, ensuring that your solar system is installed with the highest industry standards in mind. Proper installation plays a huge role in maximising the lifespan of your solar panels.

- Expertise you can trust: With over 10 years of experience in the solar industry, we know how to deliver the best solar solutions tailored to your needs. Our team of experts will ensure your system is designed to last.

- Peace of mind: We provide up to 25-year guarantees for our solar panels and 15-year guarantees for our solar batteries. This means you can have peace of mind knowing your investment is protected for decades to come.

Reach out to our solar experts today to discover how Soly can help you transition to clean, renewable energy with the best products and financing options.