Thin-film solar panels explained

When it comes to different types of solar panels, the future of thin-film solar panels is looking much brighter these days. Thin-film panels are a type of solar technology that convert the sun’s rays just like traditional solar panels. However, these panels are much thinner and more flexible.

But can these cutting-edge panels really offer a viable option for powering homes, especially here in the UK?

Indubitably, as the solar market keeps growing and changing, more and more UK homeowners are wondering if this lightweight, flexible technology can really power their homes, especially with the UK’s famously unpredictable weather.

When most people think of solar panels, they picture the familiar crystalline silicon (c-Si) type. This is because it’s the most widely used. However, there’s another exciting option out there that’s gaining traction: thin-film solar technology. While it’s been around for more than 40 years, thin-film offers flexibility and has unique properties that traditional crystalline panels just can’t match.

While thin-film solar panels might not be as efficient as monocrystalline or polycrystalline panels, their flexibility, lighter weight, and lower production costs make them a great option for specific types of solar PV system installations.

On this page, you’ll learn:

- What thin-film solar cells are and how they differ from traditional panel types.

- The advantages and disadvantages of using thin-film solar cells in the UK.

- Key considerations for performance, installation, and more.

Let’s get started!

What is a Thin-film solar panel?

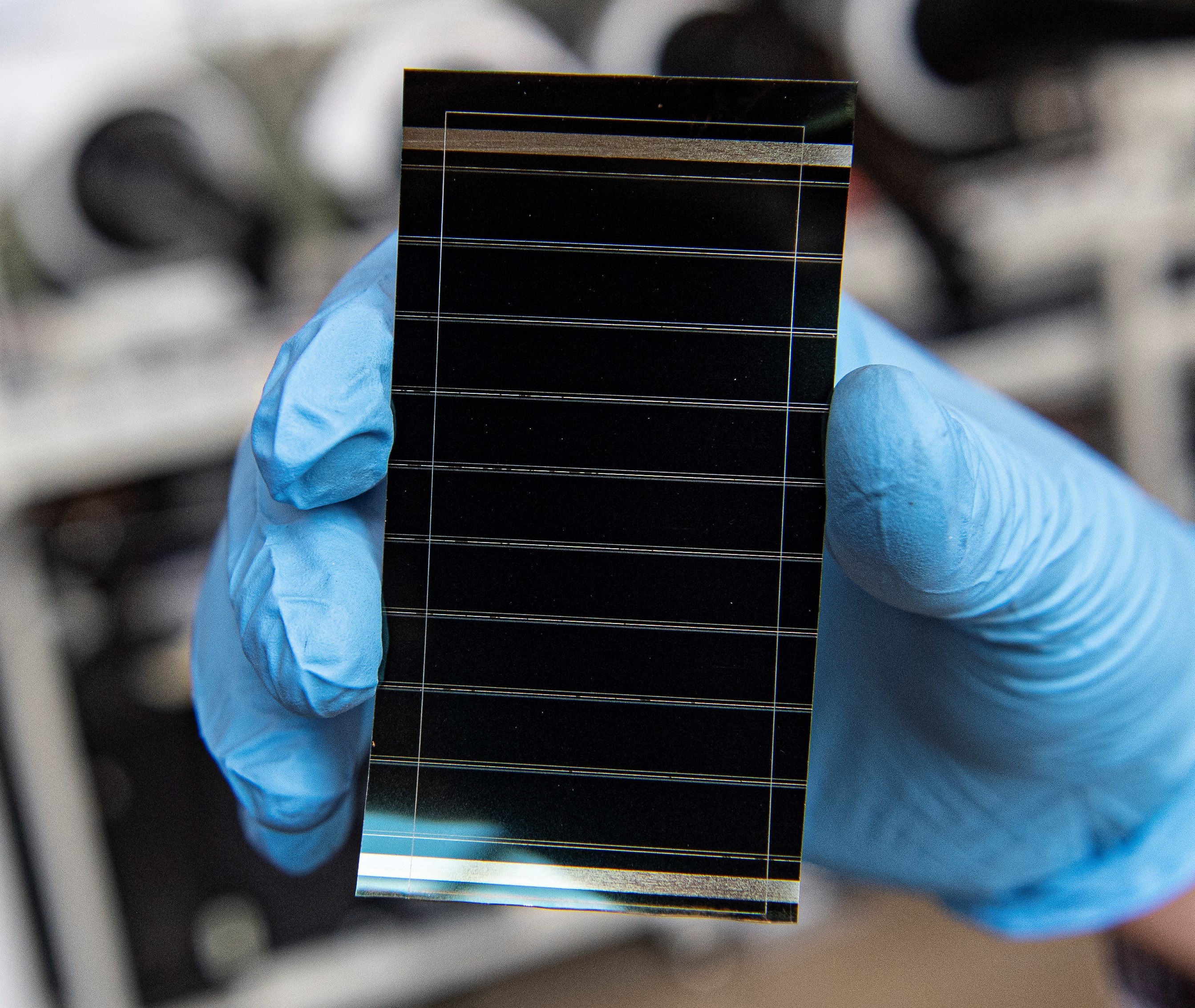

Thin-film solar cells, often called amorphous solar panels, are much thinner and more flexible than traditional ones. They’re made to easily blend with different surfaces. This makes them perfect for things like Building-Integrated Photovoltaics (BIPVs). That’s where solar panels are built right into roofs, slates, shingles, or even windows. These panels are also a great choice for more creative uses, like powering vehicles, boats, and even satellites.

Film solar panels work just like traditional ones, as they turn the sun’s powerful rays into electricity through the photovoltaic effect. However, they use newer, second-generation solar cells. These panels are made up of several ultra-thin layers of photovoltaic material.

This PV material can be applied to surfaces like glass, plastic, or metal. In fact, the layers are 300 to 350 times thinner than regular silicon panels, which is why they’re so flexible and lightweight.

Thin-film solar cells are quite different from monocrystalline and polycrystalline panels in terms of materials, efficiency, and versatility. This is because instead of using silicon crystals like traditional panels, thin-film panels are made from alternative materials.

Alternatives consist of things like cadmium telluride (CdTe), amorphous silicon (a-Si), and copper indium gallium selenide (CIGS). These materials give thin-film panels some unique advantages and characteristics.

A brief history of Thin-film solar cells: Through the looking glass

Here’s a trip through time to highlight some of the key moments in the development of thin film panel technology:

- 1961: Adolph Spakowski, head of the Photovoltaic Fundamentals Section at NASA, began testing cadmium sulfide thin film solar cells. It was so lightweight and flexible it could be rolled up for space missions. These thin-film cells were created to replace the bulky, fragile silicon panels used on spacecrafts back then. This opened the door to more efficient energy solutions for space exploration.

- 1970: Zhores Alferov’s team created the first gallium arsenide (GaAs) solar cells. This was a breakthrough that later earned them a Nobel Prize in Physics.

- 1972: The Institute of Energy Conversion was established to focus on thin-film solar research. This led to the development of early copper and silicon thin-film cells.

- 1986: The first commercially available thin-film solar cell, the G-4000, was launched. It was made from amorphous silicon.

- 1999: Spectrolab and the National Renewable Energy Laboratory created a gallium arsenide cell that achieved 32% efficiency. When this transpired, it set a new standard.

- 2015-2022: Innovations like inkjet-printed solar cells and flexible organic thin-film cells integrated into fabrics pushed the technology to new levels.

Thin-film solar technology has continued to improve over the years, and while its market share has certainly shifted, it remains an important part of the solar energy world, especially for large-scale projects in places like the United States, for instance.

How are thin-film solar panels made?

As we briefly touched on above, thin-film panels are made in a completely different way than standard solar panels. Instead of using bulky silicon crystals, thin-film panels use lightweight powdered photovoltaic materials. So, rather than rigid wafers, these panels are created by layering ultra-thin sheets of photovoltaic material onto surfaces like glass, plastic, or metal. This makes them much more flexible and all-around, versatile.

Here’s an easy breakdown of the most common thin-film materials and their efficiency rates:

Amorphous Silicon (a-Si)

Amorphous silicon is a non-crystalline form of silicon commonly used in a thin-film solar cell. It’s called “amorphous” because, unlike crystalline silicon, it doesn’t have a fixed structure. To make amorphous silicon panels, a super-thin layer of silicon, usually about 1 micrometre thick, is applied to a surface like glass or plastic.

This process makes amorphous silicon panels lightweight and flexible. When looking at thin film solar technology, amorphous silicon is perfect for situations where traditional rigid panels wouldn’t fit, like portable devices or building materials. While they aren’t as efficient as traditional silicon panels, a-Si panels have become popular because they’re affordable and easy to produce.

Cadmium Telluride (CdTe)

9% – 15% efficiency

Cadmium telluride (CdTe) is a more commonly used thin film solar technology. For that reason, it makes up a big part of the thin film solar market. It works well in lower light, making it a great choice for cloudy places like the UK. Cadmium telluride panels are also faster and cheaper to produce compared to standard solar panels, which adds to their appeal.

Additionally, CdTe panels have the shortest energy payback time of any mass-produced solar technology. What this means is that they produce more energy over their lifespan than it takes to produce them.

However, because cadmium is toxic, there are environmental concerns. This is especially the case when it comes time to disposing of the panels. In order to address this, companies have set up recycling programs to safely manage CdTe thin film technology at the end of their life cycle.

Copper Indium Gallium Selenide (CIGS): 12% – 14% efficiency

CIGS panels use a mix of copper, indium, gallium, and selenium to capture the sun’s rays. They’re highly efficient and flexible. This makes them a great option for both homes and businesses. With lab tests showing over 23% efficiency, CIGS panels have made big strides. This is why they are considered one of the most promising thin-film technologies out there.

Thanks to their flexibility, CIGS panels can be used in all kinds of applications. This includes things like curved surfaces as well as being built right into roofing materials. However, like CdTe panels, CIGS panels face some challenges when it comes to scaling up production because of the complex materials involved.

Beyond these popular second-generation materials, new third-generation thin film solar technology is starting to emerge. Here are some thin film modules that are offering even more exciting possibilities for the future of solar energy:

Organic PV Cells

18.2% efficiency

As the name states, organic photovoltaic (PV) cells are made from organic materials. Oftentimes, the organic material is polymers, which makes them affordable and flexible. They’re lightweight and have a lower environmental impact compared to other solar technologies.

Research in this area has advanced a lot, and organic PV panels are expected to become more popular, as this indeed seems to be the case for things like wearable tech and solar-powered fabrics in the future.

Suggested Diagram: Above material in use within a thin film solar panel

Perovskite Solar Cells

Up to 25.7% efficiency

Perovskites are a type of material with a special crystal structure that makes them really good at absorbing light. In fact, they’ve been getting a lot of attention lately because they could potentially match or even beat the efficiency of traditional monocrystalline silicon panels.

That said, perovskites are still in the research and development stage, but they show a lot of promise. This is because they can be applied in super-thin layers and are flexible enough for many different applications. They’re also often combined with other solar technologies to increase overall efficiency.

Quantum Dot Photovoltaics (QDPV) 18.1% efficiency

Quantum dots are tiny semiconductor particles that can be adjusted to absorb specific wavelengths of light. This QDPV technology is exciting because it could potentially reach efficiency levels much higher than traditional solar cells. Although it’s still in the research phase, the flexibility and high-efficiency potential of quantum dots make them an important part of the future of thin-film solar.

The manufacturing process for thin-film solar cells is going to depend on the material used. However, it usually involves applying a super-thin layer of photovoltaic material onto a surface like glass or plastic. This makes the panels flexible and lightweight. These layers are incredibly thin. As stated previously, they’re about 300 to 350 times thinner than standard silicon cells. This makes them perfect for uses where traditional, rigid panels wouldn’t work.

Pros and Cons of thin-film solar panels

Like anything else, thin-film solar cells have their own set of pros and cons that come along with them. This is especially the case when we compare them to traditional panels like monocrystalline and polycrystalline options. Knowing these advantages and drawbacks can help you decide if they’re the right fit for your home or business.

Let’s take a look at the pros and cons below:

Advantages

- ✅ Perform better in high temperatures: Although thin film solar cells have lower specs in many other categories, they generally have the best temperature coefficient. As a solar panel gets hotter, it produces less electricity. The temperature coefficient measures how much power output drops for every 1°C above 25°C. Mono and poly panels typically have a temperature coefficient between -0.3% and -0.5% per °C, while thin-film panels are around -0.2% per °C. This makes them better at handling the heat and losing less efficiency in high temperatures.

- ✅ Good in low light: Thin-film panels are great at capturing energy from weak or diffused light. This makes them a good fit for places that don’t get as much sunshine, like the UK, for instance.

- ✅ Lightweight and flexible: Because they’re so lightweight, thin-film panels can be installed on surfaces that might not support heavier traditional panels. This can give you more solar panel installation options.

- ✅ Faster payback: Thin-film panels tend to cost less upfront. In these cases, you’ll be able to recoup your investment faster than with traditional panels.

- ✅ Better building integration: When it comes to projects like solar roof tiles or windows, thin-film technology is great. This is where the panels are built right into the structure, offering a seamless look.

- ✅ Lower carbon footprint: Depending on the material, thin-film panels usually have a smaller environmental impact during production compared to other panel types.

Suggested Diagram: Showing thin film solar panels at work in low light

Disadvantages

- ❌ More roof space needed: Since thin-film panels are less efficient, you’ll need more of them to produce the same amount of energy that you would get from traditional panels.

- ❌ Lower efficiency: While thin-film panels typically range between 7% and 13% efficiency, monocrystalline panels range between 18%-22%. As we mentioned above, the thin-film panels would need more surface area to give you the same amount of power that you can achieve from mono panels.

- ❌ Shorter lifespan: Thin-film panels tend to have shorter lifetimes, usually between 10 and 20 years. This is much shorter when compared to the warranties we find that are offered with traditional panels of up to 25-years.

- ❌ Common glass defects: The glass in thin-film solar panels isn’t toughened like the glass in crystalline silicon panels. One of the most common issues seen is delamination. This is where the film starts to peel away from the glass backing.

When all is said and done, even with their limitations, thin-film solar cells have some unique advantages that make them perfect for certain uses. This includes things like portable solar setups, building integration, or curved surfaces.

Their lightweight design, flexibility, and strong performance in both high temperatures and low light conditions make them a great option in situations where traditional panels might not be as effective.

Additional thoughts on thin film solar cells & degradation

It’s worth knowing that how quickly thin-film solar panels wear down depends a lot on the materials they’re made from. Some materials break down faster than others.

For instance, panels made from amorphous silicon (a-Si) have been shown to degrade more quickly, with around 4% of their power output lost each year. On the other hand, panels made from materials like copper indium gallium selenide (CIGS) degrade much more slowly, losing as little as 0.2% annually. This difference in materials is why you might hear different reports on how long thin-film panels last.

Even with these differences, thin-film solar technology has been catching on, especially in the U.S. In fact, cadmium telluride (CdTe) panels made up almost 30% of new large-scale solar projects in 2022.

How much do thin-film solar panels cost?

Thin-film solar panels typically cost around £0.80 per watt. While their efficiency ranges between 7% and 13%. This efficiency is the lowest of all solar panel types (compared to the 20% or higher efficiency of top-performing panels) meaning they remain an affordable option for certain installations.

For example, if you’re setting up a small residential system in the UK with a capacity of 3kWh, using 6 435W panels:

- Total power required: 3kWh = 3,000W

- Number of panels: 6 panels, each producing 435W

- Total system output: 6 panels x 435W = 2,610W (2.61kW)

Because thin-film panels are less efficient, you might need extra space or more panels to meet your energy needs. To estimate the cost:

- Cost per watt: £0.80

- Total cost: 2,610W x £0.80 = £2,088

This gives you a ballpark figure for a 3kWh system with thin-film panels. Keep in mind that other expenses like the cost of panel installation, solar inverters, and any ongoing maintenance would also factor into your overall cost.

Before You Go All-In on Thin-film Solar Cells, Consider This

While thin-film solar cells may seem appealing due to their flexibility and lower cost, it’s truly important to look beyond the price and potential savings you could see from any government schemes.

Before you decide to take the leap and invest in this particular solar technology with a UK solar energy provider, here are a few key factors to keep in mind:

Location and sunlight exposure

In the UK, sunlight can be hit or miss. While thin-film panels perform well in low light and cloudy conditions, it’s still important to make sure your panels can capture sunlight for most of the day, and ideally between 9 a.m. and 3 p.m.

The orientation of your roof and any shading will have a big impact on how much energy your system can produce. That said, this is something you’ll want to carefully consider when planning your setup.

Roof suitability and weight limit

Thin-film solar cells are a great option for roofs that can’t handle the weight of traditional solar panels. Of course, this is because they’re so lightweight. If your roof’s structure is a concern, choosing a thin-film solution might be the way to go.

However, Soly also offers a range of monocrystalline panels, which are both energy-efficient and powerful, and can be installed on most roof types. If you’re concerned with your roof’s structure, you can have it assessed first.

Keep on reading: Is my Roof Suitable for Solar Panels?

Panel size and energy needs

As mentioned prior, thin-film panels are much less efficient than monocrystalline or polycrystalline options. So you’re definitely going to need plenty of roof space to produce that same amount of electricity that you’d get from other panel types. By figuring out your energy needs ahead of time, you can decide exactly how many panels you’ll need.

At Soly, we offer tools to help you assess your energy use. With the help of our online configurator, we can help you make sure you get the right size system for your home or business.

Durability and lifespan

Generally speaking, thin-film panels aren’t going to last nearly as long or perform as efficiently as monocrystalline panels. Soly’s high-quality mono panels come with warranties of up to 25 years. This guarantees energy production and savings for the long haul. While thin-film panels are more flexible and versatile, they usually have shorter warranties and tend to degrade faster. Inevitably, this is important to keep in mind when you’re planning for your long-term needs.

Tracking systems and efficiency

Another vantage point that comes to mind when deciding on whether or not to go all-in with thin-film panels is their flexibility, as this makes it easier to pair them with solar tracking systems that follow the sun throughout the day.

However, if you’re truly aiming for maximum efficiency and higher energy output, then Soly’s mono panels are still going to be your very best bet. This is because our panels offer top performance with less maintenance required.

By keeping the above factors in mind, you’ll be better equipped to decide if thin-film solar panels are the right fit for your home.

Suggested Diagram: Proper placement as mentioned in above points of thin film solar panels.

FAQ

What are thin-film solar panels?

Thin-film solar cells are lightweight, flexible solar panels made from thin layers of photovoltaic materials and covered with a thin layer of glass.

What is the disadvantage of a thin-film solar panel?

They have lower efficiency and shorter lifespans compared to traditional panels. Additionally, it takes more thin-film panels to do the same job that could be achieved by using fewer traditional panels. They also require more maintenance.

Are thin-film solar panels any good?

Yes, thin-film solar cells are great for certain uses, especially when flexibility, lightweight design, and affordability are important. However, they’re less efficient and don’t last as long as traditional panels, so they’re best for projects where space and top efficiency aren’t the biggest concerns.

Are thin-film solar panels expensive?

They are generally cheaper per watt, costing around £1.04 per watt.

How long do thin-film solar panels last?

Generally, a thin-film solar panel can last anywhere from 10-20 years. This gives them a much shorter lifespan when compared to other solar options out there.

How big are thin-film solar panels?

Like the name states, a thin-film solar cell is so incredibly thin. In fact, they measure anywhere from tens of micrometres to just a few nanometres. As for width, thin-film solar cells are super flexible. These solar panels can be made to fit anything, whether you choose to use them for something small like a GPS device or to cover acres of land.

How efficient are thin-film solar panels?

Their efficiency varies between 7% and 13%, depending on the material.

How are thin-film solar panels installed?

In the UK, thin-film solar panels are installed much like traditional ones—on rooftops, ground-mounted systems, or even built into the structure of buildings. Thanks to their lightweight and flexible design, they’re easier to install on a range of surfaces, especially roofs that can’t handle heavier panels.

The bottom line: Should you buy thin-film solar panels or not?

While thin-film solar panels have some exciting benefits, they’re not the best fit for every situation. With efficiency ratings between 7% and 13%, they fall short compared to traditional monocrystalline and polycrystalline panels, which often hit over 20%. That said, their lightweight and flexible design makes them ideal for certain uses, like commercial projects or portable setups.

The future of solar is definitely bright, and ongoing research is working to boost efficiency of these thin panels even more. In fact, the potential rates could reach 10%-16% or maybe even higher down the road.

According to Joshua Pearce, “There have been systematic improvements in both thin-film technology itself and its manufacture for decades. It is more than advanced enough to begin large-scale (>1GW) manufacturing today.”

He’s optimistic that thin-film technology could eventually generate electricity at prices that rival fossil fuels, even without subsidies. However, there are some challenges to keep in mind. Thin-film panels generally need more space to produce the same amount of power as traditional panels. Plus, the use of materials like cadmium raises environmental concerns, particularly when it comes to long-term disposal.

In short, while thin-film solar panels don’t yet match the efficiency or power output of traditional silicon panels, they’re still a great option for projects where flexibility, lightweight design, and cost are the main concerns. Whether for unique installations or future large-scale projects, thin-film technology could be the future of mobile and adaptable solar energy solutions.

Why choose Soly for your solar panel needs?

At Soly, we make solar energy accessible and ensure your photovoltaic system lasts as long as possible, performing at its best. Here’s why we’re the ideal choice for your solar energy journey:

- Affordable financing: We understand that upfront costs can be a barrier to going solar. That’s why we’ve partnered with Hometree Finance to make it easier for you to switch to clean, renewable power so you can start saving on your energy bills.

- Referral benefits: Soly offers the best referral scheme in the solar market. As a Soly customer, you can earn £300 for each friend you refer who installs a system with Soly—with no limits! This can significantly help reduce your payback period. For example, one of our customers, Martyn, managed to reduce his payback period by nearly a year by referring just three friends.

- High-quality panels: We use only the best solar panels, offering monocrystalline solar panels from Jinko Solar. Known for their efficiency and durability, these monocrystalline solar panels can last for up to 40 years, ensuring you get the most out of your investment.

- Trusted reputation: Soly is proud to be highly rated on platforms like TrustPilot and Google and recognized as a certified Which? Trusted Trader. We’ve built a reputation for excellence, earning the trust of countless satisfied customers, with our commitment to quality evident in every installation.

- Accredited installers: We work exclusively with local installers nationwide who are accredited by HIES, TrustMark, and MCS, ensuring that your solar system is installed with the highest industry standards in mind. Proper installation plays a huge role in maximising the lifespan of your solar panels.

- Expertise you can trust: With over 10 years of experience in the solar industry, we know how to deliver the best solar solutions tailored to your needs. Our team of experts will ensure your system is designed to last.

- Peace of mind: We provide up to 25-year guarantees for our solar panels and 15-year guarantees for our solar batteries. This means you can have peace of mind knowing your investment is protected for decades to come.

Reach out to our solar experts today to discover how Soly can help you transition to clean, renewable energy with the best products and financing options.

Discover more solar panel types:

Want to learn more about the types of solar panels before installing an energy system in your home? Check out these key resources:

- Monocrystalline solar panels explained

- Polycrystalline solar panels explained

- Mono vs Poly solar panels: What is the key difference?